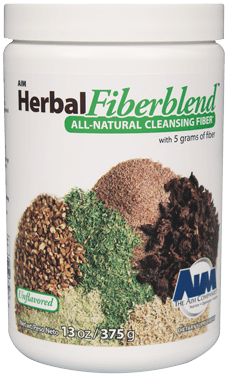

The AIM Companies produces Herbal Fiberblend and several other products at this facility. Our Quality Assurance teams monitors the process, and we thought it would be neat to show how your favorite products are made and how they are monitored for quality. Please enjoy.

The Process

This machine fills the bottles with the correct number of capsules. The tech watches to ensure that all of the cavities are full of capsules (the little black dots) as the conveyor rolls the capsules down to the bottles.

This machine fills each capsule with powder.

In this room, each ingredient is verified and weighed for each lot number and can vary from just a few kg to several hundred kg.

In this lab, each ingredient is identified by botanists prior to batching.

In this lab, each ingredient and finished lot number is tested for safety.

And that’s just a few of the steps we take to turn amazing ingredients into revolutionary, high-quality products like this one.

And that’s just a few of the steps we take to turn amazing ingredients into revolutionary, high-quality products like this one.